Unveiling Excellence: The Role of Titanium Manifold Valve Manufacturers and Industry Leaders in Modern Valves and Fittings

In the rapidly evolving landscape of industrial valves, titanium manifold valve manufacturers play a pivotal role in shaping technology, ensuring high performance, and delivering superior durability. As industries such as aerospace, chemical processing, and oil & gas demand increasingly resilient and efficient components, specialized manufacturers like Samvay Global position themselves as leaders in providing cutting-edge solutions.

Introduction to Titanium Manifold Valve Manufacturing

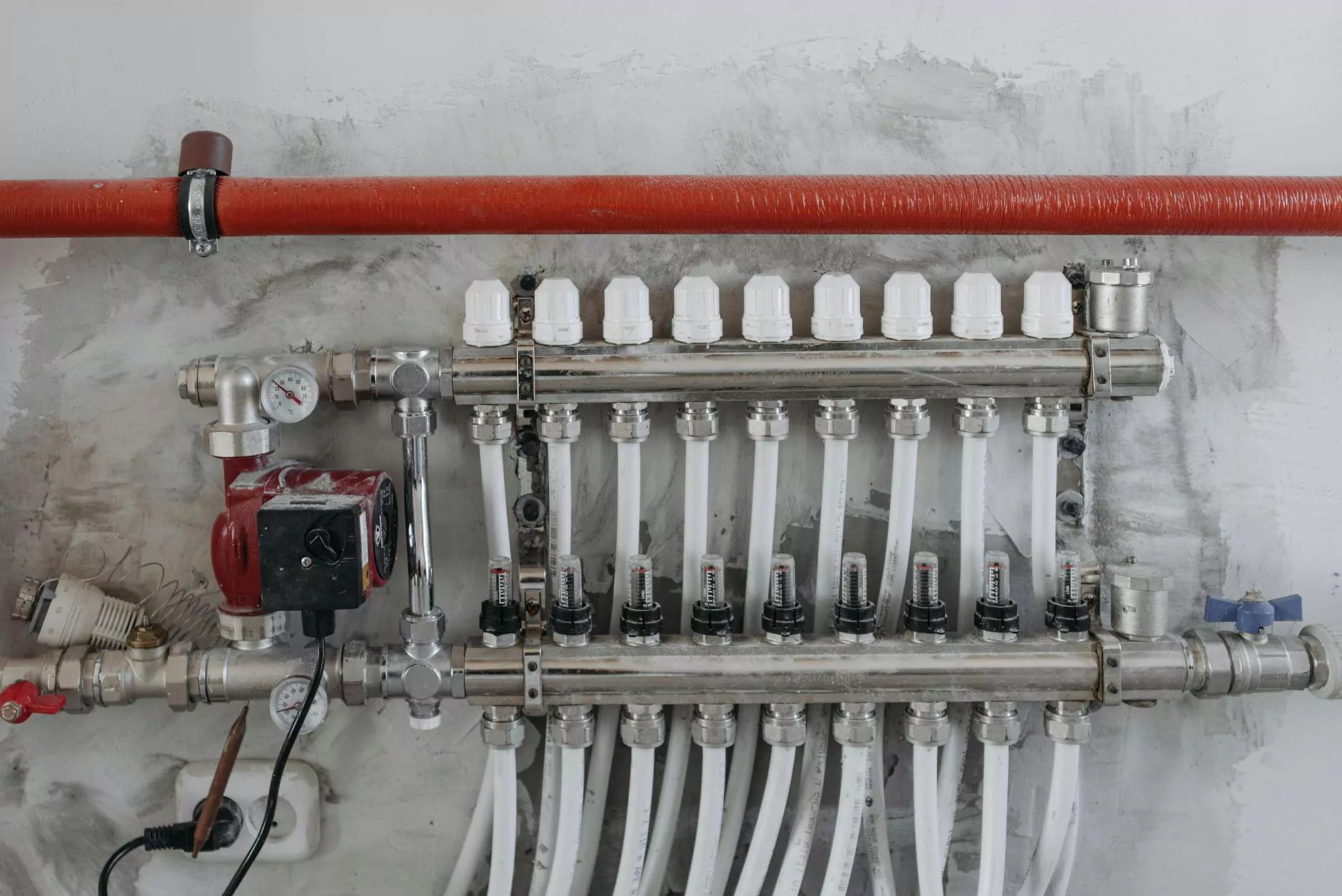

Titanium manifold valves are critical in managing high-pressure and corrosive media in complex piping systems. Their ability to withstand extreme environment conditions, combined with low weight and high strength, makes them indispensable in demanding industry sectors. The manufacturing of titanium manifolds demands attention to detail, precision engineering, and a deep understanding of material science, which top-tier titanium manifold valve manufacturers like Samvay Global excel at delivering.

Why Choose Titanium for Valves and Manifolds?

With its unique combination of strength, corrosion resistance, and lightweight properties, titanium has become the preferred material for manufacturing valves and manifolds designed for highly corrosive or high-pressure environments. The main benefits include:

- Exceptional Corrosion Resistance: Titanium forms a passive oxide layer that protects it from rust and corrosion even under harsh chemical exposure.

- High Strength-to-Weight Ratio: Unlike other metals, titanium provides durability without excessive weight, enhancing system efficiency and ease of handling.

- Temperature Tolerance: Titanium can withstand extreme temperatures, making it suitable for applications involving high heat and cold.

- Biocompatibility: This feature is particularly advantageous in pharmaceutical and medical industries, in addition to industrial uses.

Major Industries Benefiting from Titanium Manifold Valves

The strategic use of titanium manifold valves tailored by experienced titanium manifold valve manufacturers extends across multiple sectors:

- Oil & Gas Industry: Handling corrosive substances with high-pressure requirements.

- Chemical Processing: Managing aggressive chemicals without risk of degradation.

- Aerospace: Demanding weight and durability specifications in aircraft and spacecraft systems.

- Pharmaceutical & Medical: In applications where purity, corrosion resistance, and biocompatibility are vital.

- Marine Industry: Structural and fluid management components operating in saline and corrosive environments.

Qualities That Define Leading Titanium Manifold Valve Manufacturers

Achieving excellence in manufacturing titanium manifold valves involves a confluence of precise engineering, advanced material sourcing, and rigorous quality control. The top titanium manifold valve manufacturers like Samvay Global distinguish themselves through:

- Innovative Design Capabilities: Engineering bespoke solutions that meet complex client specifications.

- High-Quality Material Procurement: Sourcing certified grade 2 and grade 5 titanium for consistency and performance.

- Advanced Manufacturing Technologies: Employing CNC machining, additive manufacturing, and other state-of-the-art techniques to ensure precision.

- Comprehensive Testing & Certification: Conducting pressure testing, non-destructive testing (NDT), and obtaining industry standards certifications (ISO, API, ASTM).

- Customer-Centric Approach: Providing technical support, customization, rapid prototyping, and after-sales services.

Samvay Global: An Industry Leading Titanium Manifold Valve Manufacturer

Samvay Global has established itself as a front-runner among valve suppliers and fittings manufacturers by meticulously combining innovation, quality, and reliability. The company's specialization in titanium manifold valves is bolstered by a dedicated R&D team that drives the development of customized high-performance components tailored to client needs.

Extensive Product Range

Samvay Global offers an extensive selection of titanium manifold valves that meet diversified industrial demands:

- Single-Block and Multi-Block Manifolds: For fluid control in complex piping layouts.

- Ball & Gate Valves: For precise flow regulation and shut-off solutions.

- Check Valves: To prevent backflow under extreme operating conditions.

- Specialized Fittings & Connectors: Ensuring perfect sealing and compatibility with titanium-based systems.

Unwavering Quality Standards and Certifications

Ensuring top-grade quality is paramount at Samvay Global. The company strictly adheres to industry certifications like ISO 9001, ISO 14001, API 6D, and ASTM standards. Every product undergoes thorough testing, including pressure integrity assessments, corrosion resistance evaluation, and dimensional verification, guaranteeing clients receive only reliable and durable solutions.

Why Partner with Top Titanium Manifold Valve Manufacturers?

Collaborating with established manufacturers such as Samvay Global yields numerous benefits that propel your industrial capabilities forward:

- Custom Design & Engineering Support: Modern solutions crafted to specific project needs.

- Enhanced Equipment Lifespan: High-quality titanium components resist wear and corrosion, reducing maintenance costs.

- Operational Efficiency: Lightweight and high-performance valves optimize system performance.

- Global Supply Chain & Logistics: Reliable delivery schedules, worldwide shipping, and responsive customer service.

- Cost-Effective Solutions: Despite the higher initial investment, durability reduces overall lifecycle costs.

Emerging Trends in Titanium Valve Manufacturing Industry

The industry continually evolves, driven by technological advances and changing industry demands. Key emerging trends include:

- Integration of Smart Technologies: Sensors and automation for real-time monitoring of valve conditions.

- Additive Manufacturing: 3D printing of complex titanium components, enabling rapid prototyping and custom designs.

- Sustainable Production Practices: Emphasis on eco-friendly manufacturing processes and waste reduction.

- Enhanced Material Grades: Development of new titanium alloys with superior performance properties.

- Collaborative Innovation: Partnerships between manufacturers, research institutions, and end-users for pioneering solutions.

Conclusion: Choosing the Right Titanium Manifold Valve Manufacturer for Your Business

In an era where industrial reliability and efficiency are more critical than ever, selecting the right titanium manifold valve manufacturer can significantly impact your project's success. Companies like Samvay Global exemplify excellence through their unwavering commitment to quality, innovation, and customer satisfaction. Their expertise in valve manufacturing, fittings supply, and custom engineering solutions positions them as the ideal partner for diverse industries seeking durable and high-performance titanium components.

Partnering with a proven manufacturer ensures your equipment benefits from cutting-edge technology, rigorous standards, and tailored solutions—ultimately leading to optimized operations, reduced downtime, and substantial cost savings.

Investing in quality titanium manifold valves crafted by industry leaders is a strategic move toward technological excellence and operational resilience in your business. Embrace the future of valve manufacturing with trusted specialists dedicated to delivering beyond expectations.